Bioplastics can be distinguished based on two main criteria:

-

Source of raw materials

Bio-based: Made from renewable resources such as corn starch, sugarcane, or cellulose.

Fossil-based: Made from fossil resources (e.g., petroleum), but still biodegradable. -

Biodegradability

Biodegradable: Can be broken down by microorganisms under certain conditions.

Non-biodegradable: Does not biodegrade, even if it is bio-based.

Examples:

-

PLA (Polylactic Acid): Bio-based & biodegradable

-

Bio-PE (Polyethylene): Bio-based, but not biodegradable

-

PBAT: Fossil-based, but biodegradable

-

PET: Fossil-based & non-biodegradable

Bioplastics can also be split up in generations

🌽 1st Generation

Food-based Raw Materials

-

Raw materials: corn, sugarcane, wheat, potatoes

Examples: PLA (polylactic acid), bioethanol-based PE

-

Advantages: Widely available, established technology

-

Disadvantages: Competition with food production (food vs. fuel dilemma)

🌾 2nd Generation

Non-edible Plant Residues

-

Raw materials: cellulose, wood waste, straw, agricultural residues

Examples: Cellulose acetate, lignin-based polymers

-

Advantages: No competition with food supply, more sustainable

-

Disadvantages: More complex processing, not yet widely established

🧫 3rd Generation Microorganisms & Algae

-

Raw materials: algae, bacteria (e.g., via fermentation)

Examples: PHA (polyhydroxyalkanoates)

-

Advantages: Highly sustainable, no competition with agriculture

-

Disadvantages: Still expensive and under development

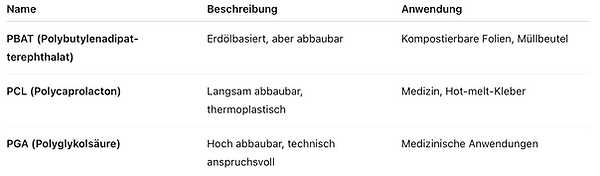

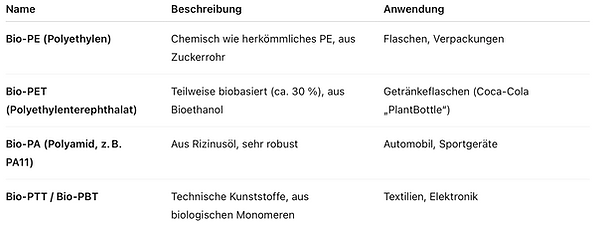

The following list provides a good overview of the currently available bioplastics but does not claim to be exhaustive due to the rapid pace of development.

🌿 biobased & bio-degradable

🌱 biobased & not bio-degradable

🧪 fossil-based & bio-degradable